Vacuum Brazing: Advanced Joining Technique

Vacuum brazing is a special way to join metals together. It uses heat and a vacuum to make strong connections between different parts. This method works well for joining both similar and different types of metals.

Vacuum brazing creates high-quality joints without using flux, which helps prevent corrosion and contamination. The process takes place in a sealed chamber where air is removed. This vacuum environment stops metals from reacting with oxygen, which can weaken the joint.

Loval specializes in vacuum brazing for nearly four decades and offers expert solutions for complex manufacturing needs.

Special brazing for Complex Products

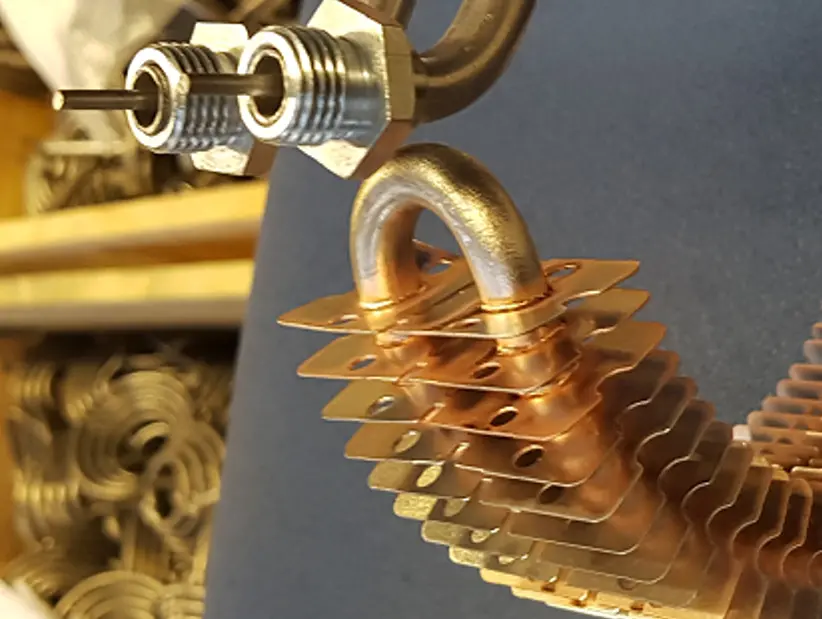

Vacuum brazing makes it possible to manufacture products that require parts in varying shapes or include potentially complex channels as well as products that are too labour -intensive to produce by conventional machining methods.

Advantages of Vacuum Brazing Over Welding

Vacuum-brazed parts are joined across their entire contact surface, whereas welding only connects parts at the edges. Hard-brazed parts are used for complex digital hydraulic blocks, special tool bits, laser-cut fabricated shape assemblies, and manifolds.

At Loval, vacuum brazing has been a core technology in our manufacturing processes since 1982. This advanced technique enables us to deliver high-precision, durable products across various industries. Let’s take a closer look at what makes vacuum brazing so essential.

What is Vacuum Brazing?

Vacuum brazing is a specialized joining process conducted in a controlled, low or zero atmospheric pressure environment within a vacuum furnace. Unlike other brazing techniques, vacuum brazing uses a filler material to join parts without melting the base materials. The filler melts and moves via capillary action into the joints, creating a strong, seamless bond. This process is not only highly precise but also environmentally sustainable, as it reduces the need for harmful flux chemicals and minimizes material waste

No corrosion

This process enhances the corrosion resistance of metal components, ensuring long-lasting durability and reliability in harsh environments

Tight seals

Vacuum brazing excels at producing perfectly airtight joints, making it ideal for industries where preventing gas or liquid leaks is critical, such as aerospace, medical devices, and vacuum systems.

Efficiently

Vacuum brazing allows for the simultaneous joining of multiple parts, improving production efficiency and reducing costs without compromising on quality.

Clean process

The controlled vacuum environment ensures high precision and quality control, producing strong, flawless joints that are crucial in complex manufacturing and engineering applications.